Dispersion in Two Line LOV

Sample and Reagent Volumes

2.2.6.F.

Efficient mixing of more than three sequentially injected zones in a single line manifold is not feasible because zones do not sufficiently overlap. To avid this limitation the confluence geometry of two line SIA system can be used in two ways:

- by synchronized merging of sample with a reagent stream

- by transferring sample from one holding coil into reagent held in the second coil

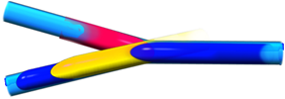

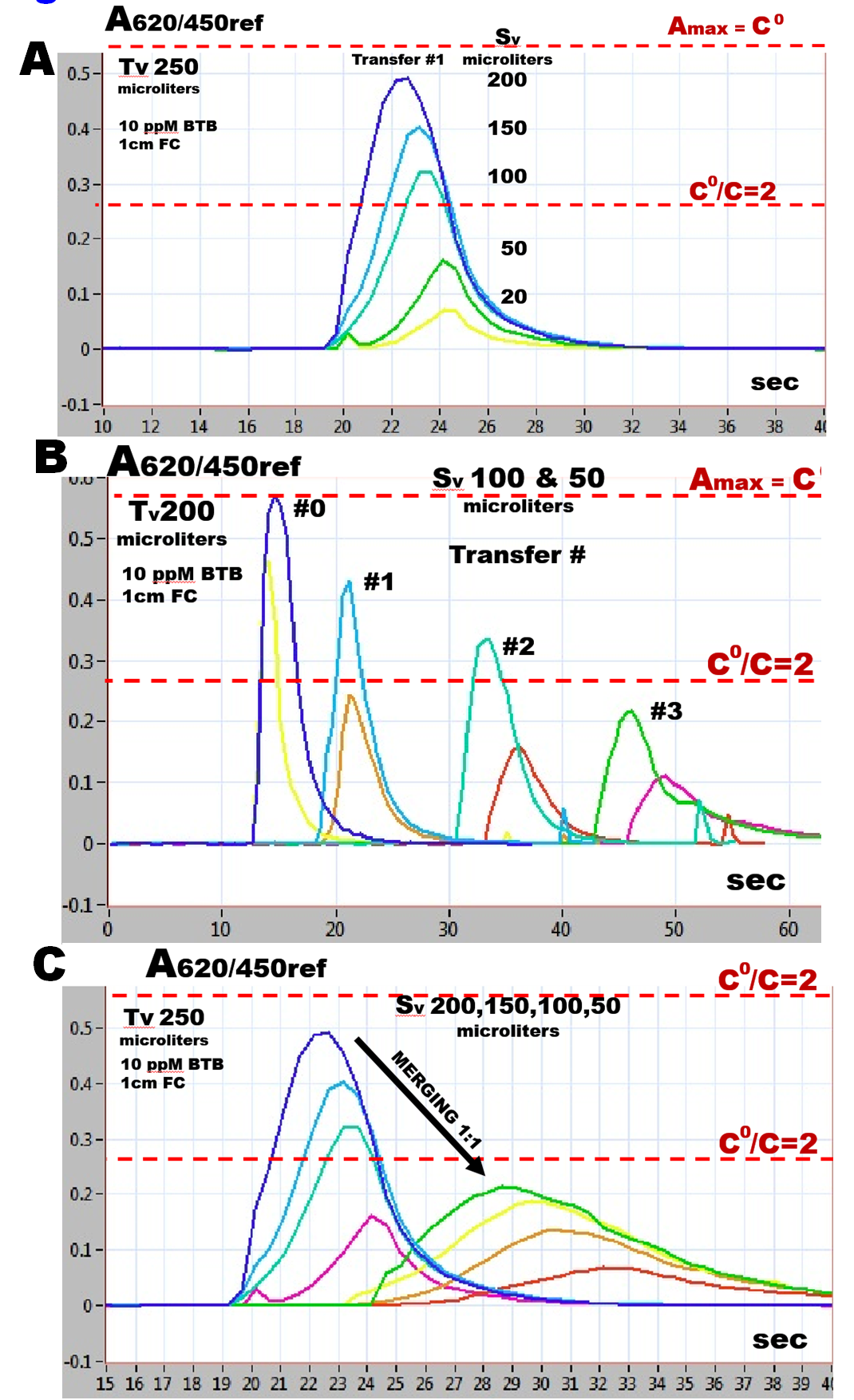

Mixing by single transfer (A), is modelled here by injecting series of increasing volumes of a dye into holding coil #1, and by transferring the dye into coil #2 by a flow reversal (by means of 250 microliter Tv volume at a flow rate of 50 microliters/sec). Next the valve was switched and the dispersed zone passed through the flow cell. Comparison of the recorded superimposed peaks (A) with those obtained in one line system (Section 2.2.6.A. Fig.B.) shows the effect of the coil to coil transfer on mixing of the dye with the surrounding colorless solution. Peaks are reshaped from narrow asymmetrical shapes, to a broad almost Gaussian shapes, their profile is reversed and the S1/2 value increased from 15 to 80 microliters.

The efficiency of multiple transfers (B) between the coils is demonstrated next, by two series of experiments using 100 and 50 microliter dye injections and by transferring them using Tv of 200 microliters repeatedly between the coils. This experiment opens the door to three or more reagent assay sequences, as explained on the next page.

Merging of sample with reagent (C) stream was done by propelling dye sample from coil#1 using Tv of 250 microliters at a rate of 25 microliters/sec into coil #2 into which solution was aspirated using Tv 500 microliters at a rate of 50 microliters/sec. As expected, all injected volumes were mixed and diluted to half . This experiment is visualized on the movie clip (2.2.6.D.).

As previously noted, dye experiments show dilution of sample by surrounding solution. In case of merging streams the surrounding solution is a reagent. For coil to coil transfer, reagent will be diluted by carrier.

NOTE: during coil to coil transfer, delivery and aspiration flow rater and volumes must be equal and all peripheral ports must isolated from central port, by turning rotor in between port position. For merging mode the reagent port is open and aspiration rates and volumes must exceed the delivery rates and volumes